Safety

Safety Policy

We keep in mind that safe and stable operations are the basis of corporate activities and prevent accidents and disasters.

We comply with laws and regulations and other standards, and strive for health & safety, security & disaster prevention and product safety.

We continuously improve health & safety management and security & disaster prevention systems and work together to engage in health & safety activities and security & disaster prevention activities.

Security & Disaster Prevention

Countermeasures against factory fires caused by static electricity.

In the case of using flammable gas as a blowing agent in the production process of foamed plastic, we prevent ignition caused by static electricity by properly installing ground wires and lowering the withstand voltage with static eliminators and water mist. In order to avoid repeating past ignition problems, we have established a system to check whether the countermeasures are being continued. Periodic safety patrols are conducted, and items for checking to see if countermeasures are functioning have been added to their checklists. We are also working to prevent recurrence of ignition problems by continuing to check both equipment and operations, such as by attaching stickers to areas where ignition problems have occurred to "visualize" the problem and alert workers during operations.

Logistics Safety

Logistics Accidents

The majority of trucking accidents occur at customer sites. 12 trucking accidents occurred in FY2022 in Japan. Backing accidents and collisions with the eaves (upper part of the building) were particularly frequent.

In order to promote safety awareness among drivers, we ask them to thoroughly check the "six directions (front, back, left, right, up, and down)" around the truck.

In addition, transport quality council meetings are held regularly with carriers at each plant to discuss safety, quality, environment and logistics-related issues. Our target number of trucking accidents for FY2023 is 6 or less in Japan. We will continue to implement various safety measures to achieve this goal.

White Logistics Movement

In response to the serious shortage of truck drivers in Japan, "White Logistics" is recommended to ensure stable logistics necessary for people's daily lives and industrial activities, as well as to be useful for economic growth. As part of our efforts to promote "White Logistics," we have declared our "Declaration of Voluntary Action for White Logistics" and are actively addressing logistics issues, including the 2024 Problem of Logistics, such as "improvement of truck transportation productivity and logistics efficiency" and "realization of a healthier working environment where women, drivers in their 60s, and others can work more comfortably.

Occupational Health and Safety

Initiatives for "Zero Lost Time Injuries"

JSP and the Group companies in Japan are promoting initiatives aimed at "zero lost time injuries”. In July 2021, we started the "Safety Baton Meeting" for business sites in Japan. This is an online meeting where, when an operational disaster or fire/ignition trouble occurs, we call not only that business site but also other business sites with similar facilities or operations to come together to discuss countermeasures.

By discussing the accident that occurred with other workplaces, the meeting will help to develop truly effective countermeasures and prevent similar accidents from occurring in the future.

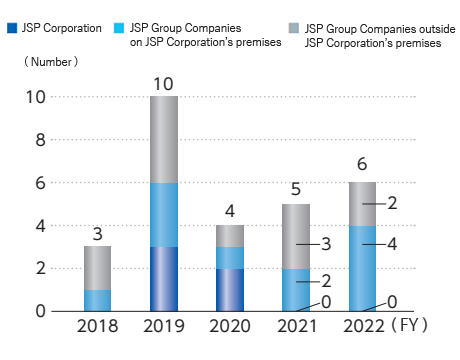

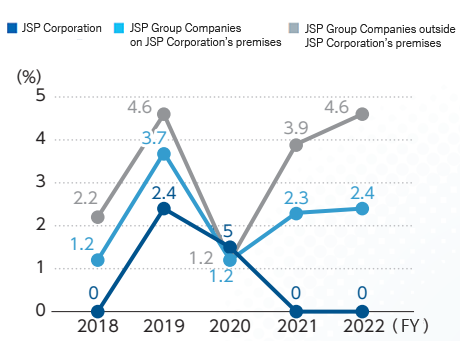

| Materiality | Item | Indicator | Target | FY2022 results |

|---|---|---|---|---|

| Occupational safety | Prevent lost time injuries(JSP Corporation and group companies in Japan) |

Number of lost time injuries Number of serious accidents |

0 cases 0 cases |

6 cases 0 cases |