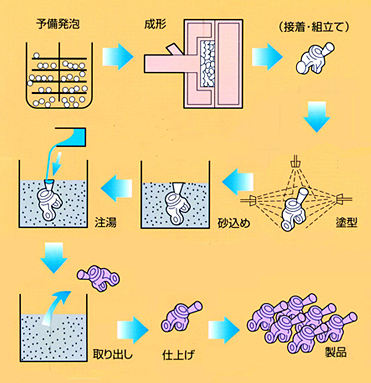

CLEARPOR is an expandable polymethyl methacrylate bead. It combines the excellent thermal degradability of polymethyl methacrylate with the superior expanding and molding properties and rigidity of polystyrene, making it suitable for the lost foam casting methods.

Compared to molded products made of expandable polystyrene (EPS), the superior thermal decomposability of this material allows for castings products with fewer soot defects and less carburization. In addition, dimensional changes in molded products are smaller, resulting in more precise models.

HEATPOR GR is an expandable polyacrylonitrile/styrene bead whose molded products have excellent heat resistance, with dimensional change within ±1% at 90°C. It also has excellent oil resistance, and HA300 and HLA300 are resistant to gasoline and kerosene. Like expanded polystyrene, it is a foam with an independent cell structure, making it suitable as a heat insulator due to its low thermal conductivity and water absorption. Molded products of HEATPOR GR are used as roofing underlayment, heat insulation and thermal insulation material for tanks and solar equipment, heat insulation material for hot water pipes, parts trays for robot lines and structural components requiring heat resistance (automotive parts, home appliance parts, etc.).

ELEMPOR NEO is an expandable polyethylene/polystyrene composite bead developed using foaming agent impregnation technology. It is softer and more tenacious than expanded polystyrene and expanded high impact polystyrene, making it suitable for shock absorbers and cushioning materials for heavy objects. It can be pre-expanded and molded using EPS molding machines.

ARGILIX is a thermoplastic elastomer bead foam. It exhibits softness and excellent recovery and resilience properties that cannot be obtained with conventional bead method products. It is expected to be used in a wide range of applications, including sporting goods, toys, playground equipment and bedding.

FOAMCORE combines the expansion and blow molding process simultaneously into a single process tool, that offers superiority in terms of lightweight, strength, thermal insulation and recyclability. FOAMCORE consists of a solid outer layer and an expanded core, expanding the possibilities for mono-material components. It has been applied to prefabricated bathrooms, automotive parts and marine floats.

ACRYACE is a non-foamed extruded sheet that can be made of various resins such as MS or polystyrene. ACRYACEMS is an extruded sheet of MS resin copolymerized with MMA (methyl methacrylate monomer) and SM (styrene monomer). It is used in the following areas.

[Application Examples]

- Optical field (lens installation base plates, diffusion plates, etc.)

- Industrial fields (frozen/refrigerated showcase faceplates, etc.)

- General (picture frame faceplates, poster panels, etc.)

- Construction (interior doors, stairway panels, etc.)

ACRYACE UV is transparent sheet made of MS resin with good adhesion to UV-curable ink. ACRYACE DS is a design-oriented extruded sheet with excellent design characteristics such as a checkered pattern and is used as a glass substitute for interior doors, furniture and commercial space displays.