ARPRO is an impact energy absorbing material, manufactured worldwide, and its unique combination of material properties makes it an ideal material for a wide range of product applications. As a high-performance engineering material, ARPRO provides a range of performance benefits for both manufacturers and end users, including energy absorption with structural strength yet very low weight, chemical resistance, thermal, acoustical and sound insulation. ARPRO is recyclable. Typical applications are automotive safety components, multi-purpose transportation packaging (dunnage), HVAC housings and many others. For product specific information please visit ARPRO.com .

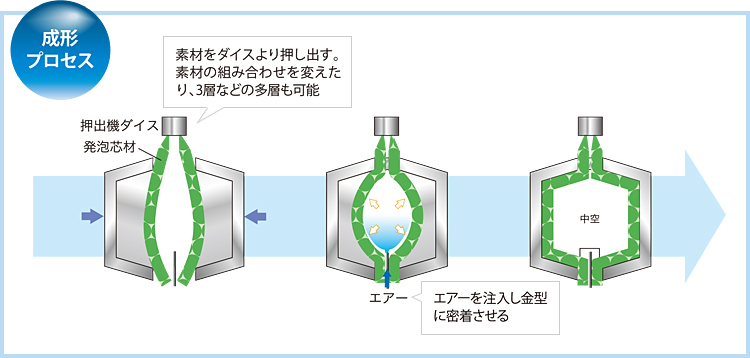

SUPERFOAM is a technology that forms hollow foam by foaming the blown resin itself. In addition to the lightweight and heat-insulating properties unique to foam, it can meet various needs, such as products with sound deadening properties.

When used in automotive air conditioning ducts, the weight can be reduced to less than half that of simple blown products (solid products). Its sound deadening properties can also reduce noise emitted from air conditioners.

ELEMPOR NEO is an expandable polyethylene/polystyrene composite bead developed using foaming agent impregnation technology. It is softer and more tenacious than expanded polystyrene and expanded high impact polystyrene, making it suitable for shock absorbers and cushioning materials for heavy objects. It can be pre-expanded and molded using EPS molding machines.

STYRODIA is expandable polystyrene beads, whose molded products have excellent heat insulation and shock-absorbing properties. It is widely used in Japan for food packaging materials, cushioning packaging materials, building insulation materials and civil engineering materials. Used molded products can be recycled as raw materials for a wide variety of re-manufactured products. The material recycling rate in Japan is more than 50%, and 90% if thermal recycling is included.

HEATPOR GR is an expandable polyacrylonitrile/styrene bead whose molded products have excellent heat resistance, with dimensional change within ±1% at 90°C. It also has excellent oil resistance, and HA300 and HLA300 are resistant to gasoline and kerosene. Like expanded polystyrene, it is a foam with an independent cell structure, making it suitable as a heat insulator due to its low thermal conductivity and water absorption. Molded products of HEATPOR GR are used as roofing underlayment, heat insulation and thermal insulation material for tanks and solar equipment, heat insulation material for hot water pipes, parts trays for robot lines and structural components requiring heat resistance (automotive parts, home appliance parts, etc.).

FOAMCORE combines the expansion and blow molding process simultaneously into a single process tool, that offers superiority in terms of lightweight, strength, thermal insulation and recyclability. FOAMCORE consists of a solid outer layer and an expanded core, expanding the possibilities for mono-material components. It has been applied to prefabricated bathrooms, automotive parts and marine floats.

P-BOARD is a foamed polypropylene board with persistent antistatic properties that can be used in a wide range of applications. It meets a variety of needs by adding persistent antistatic, shock-absorbing and conductive functions.

Excellent processability facilitates cutting, punching and heat molding. It continuously prevents the generation of static electricity due to friction during transportation and the function does not deteriorate even after repeated washing or strong friction. Relatively high heat resistance among general-purpose resin products and can be used under high temperatures.

It is environmentally friendly, hygienic and safe. It is also easy to recycle and does not emit toxic gases when incinerated.